Panel Repair and Manufacturing

THE COACH BUILDING SHOP AND MACHINE SHOP

In the Machine Shop panels are made to suit your design or to replace rusted, damaged or missing parts from your vintage and classic car. After the panels are hand formed they are usually fitted to one of the vehicles in the Coach Building Shop. However if you are a home restorer we are happy to manufacture panels to suit your needs for your project at home.

In the Coach building shop we also carry out repairs to accident damaged panels. We use traditional repair techniques like file finish, heat shrinking and lead wiping. We finish all repairs to a very high standard and welcome your inspection during the manufacturing or repair process.

We Repair and Manufacture.

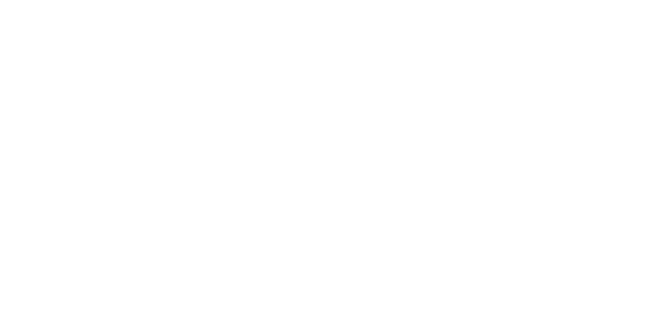

Floor Pans

Bonnet Panels

Mud Guards

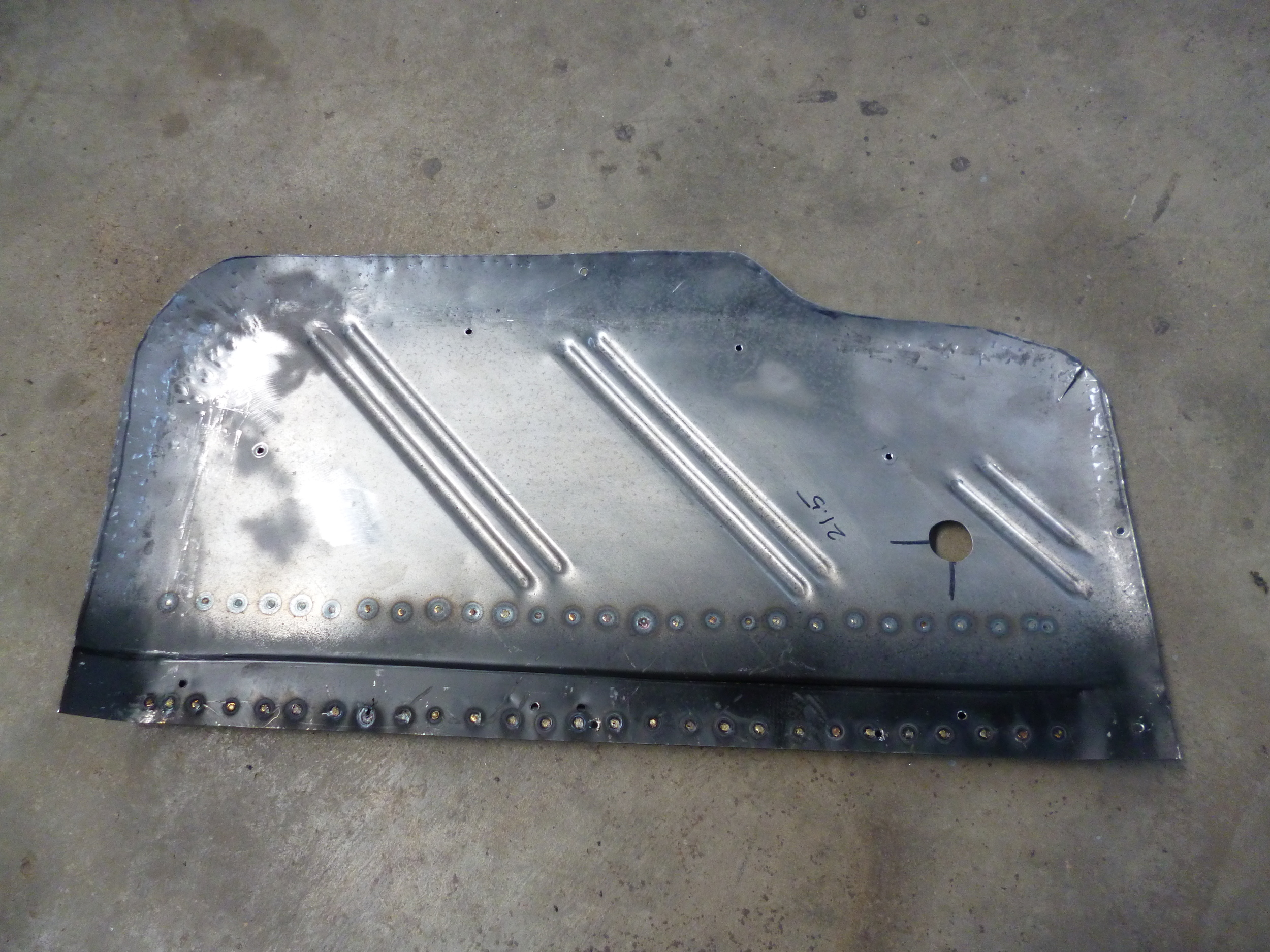

Door Skins

Door Frames

Transmission Tunnels

Wings, Spoilers Ducts and Dams

Radiator Surrounds

Beaver Panels

Inner Door Sill Panels

Outer Door Sill Panels

Spare wheel well

Turrets (Roof panels)

When it comes to manufacturing we can use the original panels as a template. We can also use the original timber framing or steel frame to find the shape, position and size of the original panels. In some cases we can use cardboard patterns, drawings and photos to build panels you require. When large or complicated panels are being hand formed a timber buck is manufactured to aid the build of the panel by giving a solid template to follow. We can manufacture panels from high quality 1 mm Coach Building steel, 1mm black steel, 1mm or 1.6mm Zinc Anneal, Aluminium 0.9 - 1.2 - 1.6 - 2.0 mm , 1001 '0', 3003 H14, 5005 H34, 6006 T6. Stainless steel, Brass and Copper.

The panels are hand formed by various techniques and machinery. We cut, roll, fold, wheel, shrink - stretch and punch shapes into sheet metal to form panels. To find out more about the machinery and how they are used in the Machine Shop please view the Workshop tour.

Once the panels are manufactured they are fixed to the vehicle in various ways in the Coach Building Shop. Repair panels are welded into place by various techniques. By far Oxy and Acetylene is still the preferred choice because of its consistency, its speed and the ability of releasing the weld with a hammer and a dolly to counter the shrinking produced by the welding/heating process. It is possible to file finish panels that have been welded by Oxy and Acetylene. We also use T.I.G and M.I.G welders along with resistance or spot welding to manufacture and fit panels.

Chevrolet 1934 rear guard repair.

Riley 1937 work in progress.